SIGN UP FOR REAL ESTATE MARKET NEWS & TRENDS

Hythe Expansion Project - Sour Gas Processing & Sulphur Recovery

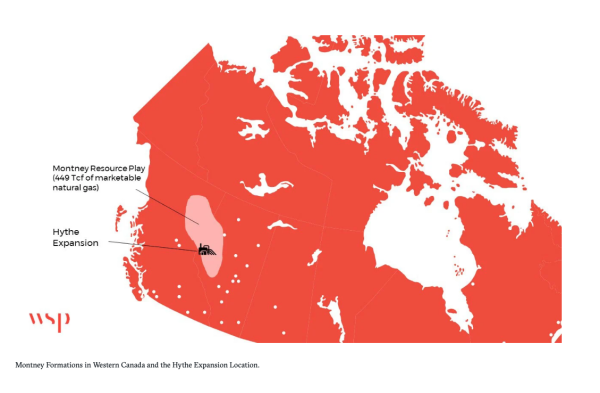

One of the most prolific unconventional resource plays being developed in Western Canada is the Montney. WSP is delivering a unique solution through the Hythe Expansion Project by leveraging innovation and exceeding industry standards that will deliver significantly reduced GHG and SO2 emissions compared to conventional facilities.

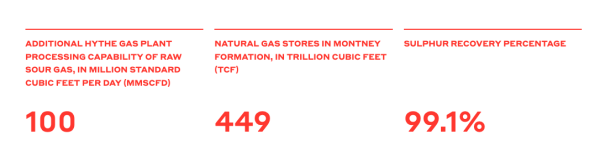

Canadian natural gas is one of the most environmentally responsible energy sources in the world. Currently, one of the most significant resources under development in Western Canada is the Montney formation. With an estimated 449 trillion cubic feet of recoverable natural gas, unlocking the Montney is the key to the future of resource development in Canada as a clean alternative to lower Green House Gas (GHG) emissions by 40 percent.

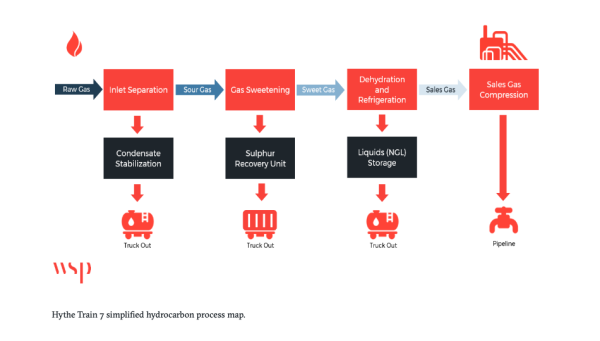

The expansion of Veresen Midstream Limited Partnership’s (VMLP) Hythe Gas Plant included the installation of a new train (Train 7) at the existing facility and a suplhur recovery unit, which was the first of its kind in Alberta since the 1990s. When completed, the Train 7 Expansion will process an additional 100 MMscfd of raw sour gas to produce marketable sales gas, natural gas liquids, and sulphur products. VMLP is committed to meeting or exceeding existing safety and environmental laws, regulations and appropriate industry standards at each of their facilities. By leveraging innovation and exceeding industry standards, the Hythe Expansion will deliver significantly reduced GHG’s, methane, nitrogen oxide (NOx) and sulphur dioxide (SO2) emissions compared to conventional facilities.

Our Approach

WSP’s approach ensured that this project incorporated responsible and efficient resource development to power a lower carbon future. The natural gas produced by this project will be a clean option used for meeting energy demands of the future while supporting the increased demand to feed the local economy and to diversify to consumer goods.

WSP contributions supported VMLP attaining regulatory approval, which was acquired in 2018. After providing conceptual and detailed design, our team was responsible for ensuring all construction drawings were provided to VMLP to support the construction and fabrication activities. Construction planning is the responsibility of VMLP with WSP providing engineering support through construction, commissioning and turnover to Operations.

To meet our client needs WSP adapted a flexible project delivery approach, including:

- The use of client specific RFI tools.

- Direct-issue of engineered deliverables to contractors and managing on-line digital reviews of WSP stick-file drawings.

- Customized execution strategies to maintain project schedules while executing out-of-sequence engineering.

- Digital markups of engineering drawings, vendor documentation and project deliverables resulted in improved access and enhanced the client/engineer collaboration process.

included the installation of a new train (Train 7) at the existing facility and a suplhur recovery unit, which was the first of its kind in Alberta since the 1990s. When completed, the Train 7 Expansion will process an additional 100 MMscfd of raw sour gas to produce marketable sales gas, natural gas liquids, and sulphur products. VMLP is committed to meeting or exceeding existing safety and environmental laws, regulations and appropriate industry standards at each of their facilities. By leveraging innovation and exceeding industry standards, the Hythe Expansion will deliver significantly reduced GHG’s, methane, nitrogen oxide (NOx) and sulphur dioxide (SO2) emissions compared to conventional facilities.

Project Challenges

The cost and timeline required to find a suitable formation and develop infrastructure for hydrogen sulphide (H2S) disposal would have made the Hythe Expansion project potentially non-viable from an economic and opportunity standpoint. Converting the acid gas stream to a marketable commodity (sulphur) and reducing the plant energy consumption by selecting a processing train over acid gas injection was the key innovation in making this project a reality.

The completion of the Train 7 expansion brings the total processing capacity of the Hythe Gas Plant to approximately 500MMscfd. The expansion includes the installation of:

- Inlet separation and gas heating

- Sales gas compression and filtration

- H2S and carbon dioxide (CO2) removal by Amine processes

- NGL recovery and storage

- Dewpoint control by Mechanical Refrigeration

- Sulphur recovery and shipping

Minimizing Environmental Impact

With the need to be more sustainable when it comes to natural resource development the Hythe Expansion has incorporated significant measures into the design to minimize emissions of greenhouse gases and pollutants. WSP incorporated innovative design features into the project including:

- Achieving a 99.1% sulphur recovery (exceeding the 98.7% specified by the Alberta Energy Regulator);

- Utilizing electric drives for pumps and compressors, LED lighting and low NOx burners for process heating;

- Expanding an existing facility to minimize the overall land disturbance compared to building a new greenfield facility;

- Utilizing existing condensate storage with a vapour recovery unit to capture and recycle methane in lieu of venting or flaring.